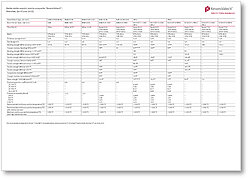

Standard materials

Here you find a short description of the types of “Keramikblech” are offered. We will advice you to find out which type of “Keramikblech” is the best for our application.

SvM1514N

For applications up to 950°C. This material can be used as production components for aluminum casting and furnace doors casings. The production components for aluminum casting can be surface hardened with zirconia and can be coated with boron nitride to get a better protection against aluminum.

MvM1415N

For applications up to 1150°C. This material is good for tubes with small diameters and for structures with smooth surfaces.

MvM1415N-550

For applications up to 1150°C. This type is used for structures with large wall thickness and attractive component prices. Examples are butterfly valves and sliders.

AvM1415N

For applications up to 1300°C where components with thin wall thickness and good mechanical properties are needed. This material is used for burner tubes and hot gas leading components in facilities for testing exhaust systems.

AvM1415N-3000

For applications up to 1300°C where components with large wall thickness with moderate mechanical properties are needed. This type is used for large structures.

can be found on the Downloads

page, as well as further data sheets

and publications.