Oxide/oxide ceramic matrix composite “Keramikblech”

The technical ceramic for high temperature applications for industry and research

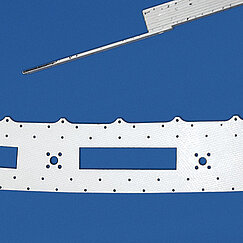

named “Keramikblech” (sheet ceramic) is an oxide fiber reinforced oxide ceramic, a part of the material group called ceramic matrix composites. This material is an advanced technical ceramic for developers, designers and users, who want to design thin walled, thermal shock resistant and oxidation resistant ceramic components for continuous service temperature up to 1300°C. “Keramikblech” replaces thermal and mechanical highly loaded sheet metal components, which should not be distorted or should not be oxidized.

Components that have performed well:

- production parts for aluminum casting

- furnace components like furnace doors, furnace linings, hot gas butterfly valves, sintering aids

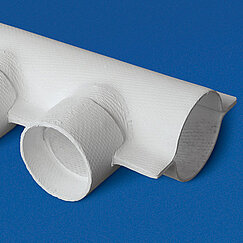

- burner tubes, flame tubes, burner components and combustion chambers

- structures for extreme thermal shock

- special components for aeronautics and astronautics