CMC types: the „hot all-rounders“

Composites World currently describes the development as the beginning of “a new era for ceramic matrix composites“.

In fact, the use and further development of CMC has accelerated significantly since the 1970s. This material has now become indispensable in many segments of industry and research.

But the goals are ambitious, because in order to develop more sustainable products in the required variety, temperature resistance is just one of the numerous requirements. Motivation and confidence have grown on all sides, especially as the successes reveal the sought-after CMC and OCMC types in their entirety as true all-rounders.

Industrial oxide fiber production in Europe kicks off.

In Denkendorf, the DITF conducts extensive research on new “recipes” and the optimization of manufacturing processes for oxidic fibers through to further processing. In the near future an industrial production with their partner Saint-Gobain could be successful for the first time and significantly improve the profitability of the end products through lower fiber costs.

Our tests in collaboration with the DITF, whose oxide fibers could prove their high quality in unidirectional and woven fabrics during a project with BASF, were successful. DITF fabrics were further processed in-house (in Sielmingen) into finished OCMC demonstration objects.

The editors of Composites World have contacted key players in CMC's research, development and production sectors, (including us). The result is an excellently researched article which provides a global overview and increases the excitement because:

“Everything below 1000 °C leaves us cold.”

Read the original article:

“DITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more”

– External link to Composites World, please take a look at the Privacy Policy. –

(As of november 2023)

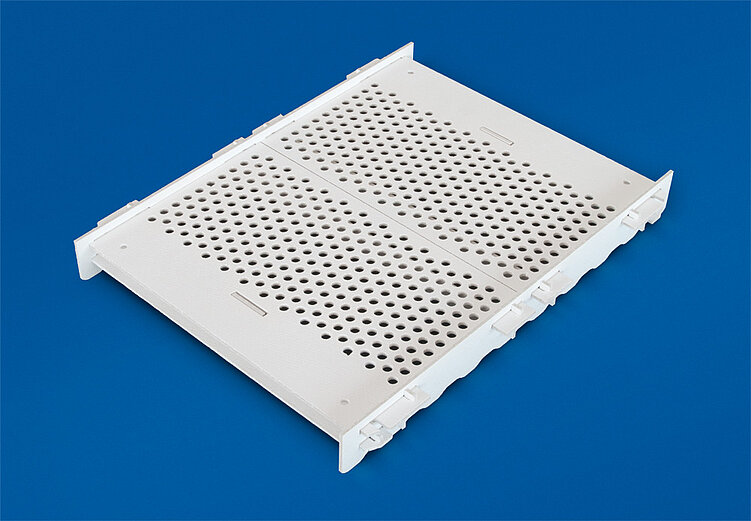

A durable lightweight:

the charging racks made of Keramikblech®

Thin-walled frame constructions made of sheet ceramic, (Keramikblech), have proven to be robust after more than 400 successful cycles. The material properties, weight and mechanical strength were explicitly adapted to the extreme challenges at the site of application.

Charging racks made of Keramikblech offer special advantages for long-term applications up to 1000 °C, not only due to their low thermal expansion (approx. 50 % of steel), their thermal shock resistance, but also due to their stability and lightness.

The material reliability also enables excellent service life. There are hardly any limits to the variety of shapes.

Case studies “Keramikblech”: "An enabler under demanding conditions"

(External link, please take a look at the Privacy Policy.)

(As of february 2022)

The homogeneous bending strength level of isotropic CMC materials makes them suitable for multiple applications.

Bending tests of isotropic and anisotropic CMC plates provide new view into the interaction of fiber and matrix.

The samples of the material FW12 have been tested in 7 directions: 0°, 15°, 30°, 45°, 60°, 75° and 90°. Significant differences in the bending behaviour of isotropic and anisotropic material samples could be found:

Bending strength behaviour of the anisopropic plate:

- Maximum loads can be absorbed in the fiber direction 0° and 90°. At an angle of 45°, a flexural strength of only approx. 50% of the 0° and 90° fiber direction is measured. (Graphic: blue curve)

Bending strength behaviour of the isopropic plate:

- The samples are showing a nearly constant bending strength at all test angles, (0° – 90° in 15° steps). In the course of the tests carried out, a maximum deviation of only about 15% occurred. (Graphic: red curve)

Conclusion:

The isotropic OCMC material suits far better for multi-axis stress conditions than the anisotropic OCMC material.

Full details of the experiment can be found in the original document at:

Test implementation: Sandra Leonhardt and Frank Walter, Author: Sandra Leonhardt, published by: © Walter E. C. Pritzkow Spezialkeramik

(As of february 2021)

The 3M Nextel® 610 oxide fibre fabric is an essential “basic material” of OCMC’s1. Therefore, its purchase price is a decisive cost factor in the production of simple and complex parts made of Keramikblech®.

As a result of a series of development stages with 3M Nextel® 610 fabrics, the DF11-3000 fabric had already proven itself in the production of OCMC last year. This had already made a cost reduction of ten to fifteen percent in the production of Keramikblech® possible2.

Depending on the requirements and complexity of the components, the new type DF13-4500 allows a cost reduction of up to 67%

Our components made of Keramikblech® have to endure a lot and before their use they have to pass through the "torture chamber": temperature, thermal shock and mechanical stress. The results of the quality tests using the new fabric were encouraging in this regard. Even more exciting: the price-performance ratio.

Go-ahead for use in Keramikblech® manufacturing

DF13-4500 is expected to be available for component manufacturing from April 2021.

The focal point of energy technology

Solar absorber components made of Keramikblech®:

Recently, sheet ceramic components for a volumetric receiver of the Noor III solar tower plant have been completed. Due to its exceptional properties, sheet ceramic is interesting for hot gas generation in this type of solar energy conversion, where thermally and mechanically highly loadable components are required.

The American company Wilson Solarpower Corporation had developed the technical basis for the Brayton Cycle CSP* system, which thereupon has been marketed as 247Solar Plant™ by 247Solar Inc. This proprietary CSP* technology uses hot air as a heat transfer medium instead of the usual steam or nitrate salt.

The solar absorber, designed as a volumetric receiver, is a central component of the Noor III solar plant in Morocco. On top of the solar power tower, it heats the air passing through up to 970 °C. In combination with a microturbine, this hot air is used to generate solar electricity.

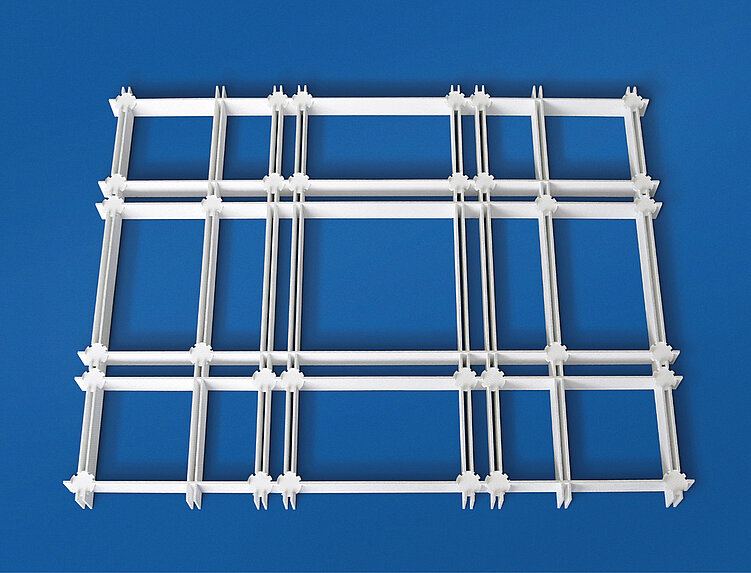

The basket like structure made of sheet ceramic, (Keramikblech), holds the ceramic SiC foams together, where the heated air flows through. The combination of SiC foams as the absorber material and the supporting structure made of sheet ceramic, make the absorber perfectly suited for these extreme challenges and will guarantee a long-term use at the same time.

In order to make a contribution to the energy supply of our common future, we were glad about this task.

Thanks to our customers and partners for their great cooperation.

*CSP = Concentrating Solar Power

Further information on this subject:

247solar.com,

(External link, please take a look at the Privacy Policy.)

247Solar Plants 3D Animation,

(External link, please take a look at the Privacy Policy and Terms of Use.)

(As of august 2019)

Dawn of VTOL with sheet ceramic technology

September 17, 2018:

Jetoptera, Inc. has commenced the Vertical Take Off and Landing (VTOL) test campaign, demonstrating capabilities to vertically take off and hover a testbed of more than 50 kg.

(As of oktober 2018)

A vertical launch of groundbreaking success:

the tests show an excellent thrust vector control via a swiveling Fluidic Propulsive System™, (FPS™), which can be rotated more than 90 degrees out of the horizontal position for VTOL. The platform demonstrated the excellent maneuverability and vertical takeoff capabilities. In addition, findings on demonstrate Short Take-Off and Landing / STOL capabilities.

This is the first time that the thin-walled thrusters made of sheet ceramic were employed for a VTOL test and its low weight properties enable the FPS™ capabilities.

All Jetoptera products except the J-55, including the four-seat VTOL aircraft “Jetoptera 4000”, are employing the proprietary fluidic propulsive system FPS™.

Further information can be found on the

www.jetoptera.com,

(External link, please take a look at the Privacy Policy.)

jetoptera.com/news/,

(External link, please take a look at the Privacy Policy.)

The-J2000-flying-car,

(External link, please take a look at the Privacy Policy.)

Jetoptera FPS™ system completes another flight test campaign

A second model – this time a glider – took to the skies on July 5th, 2018, powered solely by the Fluidic Propulsion System™.

The successful test flight demonstrates the flexibility of the propulsion FPS™ concept used on various configurations of the airframe. The glider will be used as test bed for future shapes of the thrusters, including round and non-round, enabled by Walter E.C. Pritzkow special ceramics construction method.

The advantages of the system: small size, distributed thrust and high speeds, low weight, simplicity, considerable payloads and exceptional maneuverability are obvious, and its scalability can be extended to the new concepts of urban air mobility.

These successful flights strengthen the cooperation between Walter E. C. Pritzkow special ceramics and Jetoptera, Inc. The ultralight ceramic sheet thrusters were key to keeping the weight of the FPS low and the thrust to weight ratio high. The flight and further technical details can be seen on the Jetoptera, Inc. Company website:

jetoptera.com/news/,

– External link, please take a look at the Privacy Policy. –

(As of july 2018)

Lift-off: „Keramikblech“ thrust nozzles in test flight of an unmanned aerial vehicle (UVA)

For the first time a component made of sheet ceramic, built into the model “J55”, takes to the skies. Edmonds / Washington-based Jetoptera, Inc. developed the Fluidic Propulsion System™, an innovative propulsion concept for an unmanned aerial vehicle. For the first time the fluidic propulsion technology was implemented on the airframe. A consistent development of fluid mechanical components, the implementation of the latest ceramic technologies and innovative manufacturing techniques are components of the compact, revolutionary design.

The sheet ceramic were incorporated into the thrusters of the model Jetoptera J55, due to the low density of the ceramic material, which is only 36% of the steel density, as well as its high thermal load capacity, especially developed for this challenging task.

The test flight of the Jetoptera prototype on April 26 this year was a world premiere in terms of design and drive technology for unmanned aerial vehicles, but also in regards of the wide range of applications of the oxide ceramic fiber composite "sheet ceramic" in industry and research.

(As of may 2018)

More about „Jetoptera“,

(External link, please take a look at the Privacy Policy.)

article „Fluidic propulsion™ takes off“,

(External link, please take a look at the Privacy Policy.)

Jetoptera on Linkedin,

(External link, please take a look at the Privacy Policy and Terms of Use.)

“Keramikblech” flame tubes 15 years in successful use

Already 15 years ago, in 2002, flame tubes made of “Keramikblech” (sheet ceramic), were delivered for burners from the company Weishaupt for the first time. The first flame tube was installed by the large bakery Wendeln near Munich, (at that time already Kamps), in a baking line, on which the crispbread “Lieken Urkorn” was produced. This production line was sold in 2003 to Wolf Süsswaren in Arnstadt, Thuringia, where a second baking line was also equipped with flame tubes made of “Keramikblech". Both plants are still in operation. Today this industrial bakery is called “Grabower Süsswaren”.

The lifetime of metal flame tubes in 2002 was approximately 1000 hours. The durable flame tubes made of sheet ceramic are only replaced if they are mechanically damaged during maintenance. Therefore a more than 50,000 hours lifetime of “Keramikblech” flame tubes is about 50 times higher than the lifetime of metal flame tubes.

Further flame tube types for “Weishaupt burners” are mainly used in crematoria. In these applications the lifetime of 10 weeks is extended to more than 2 years.

See also:

Sliding carriage of the first generation after 2800 cycles:

The sliding carriage of the 1st generation, shown above, passed through 2800 cycles by now but still works with its fissures. The sliding carriage of the 2nd generation currently passed through 920 cycles.

The application temperature of these sliding carriages is between 1000 – 1140 °C. The cycle time amounts approx. 2 hours. It's loaded with test bodies, is pushed into the hot stove and pulled out again after a not known residence time.

(As of april 2016)

Further publications you can download as PDF file.

(As of february 2015)